-

PowerTools

- Corded Power Tools

-

Cordless Power Tools

- Batteries & Chargers

- Belt Sanders

- Biscuit Jointer

- Caulking Guns

- Concrete Vibrators

- Die Grinder

- Dremel Cordless

- Fan

- Heat Gun

- Inflators

- Mag Drill

- Mixing Drills

- Ratchet

- Rebar Bender/Cutter

- Rivet Guns

- Routers

- Staplers

- Vac

- Wall Chasers

- Blowers

- Drills

- Cordless Kits

- SDS Hammer Drills

- Drywall Cut-Out Tool

- Glue Gun

- Grease Guns

- Grinders

- Inspection Camera

- Laser Levels

- Multi Cutter

- Multi-Tools

- Nailers

- Nibbler

- Planers

- Radios

- Sanders

- Saws

- Shears

- Thermometer

- Torch

-

Air Tools

- Air Blow Gun

- Air Caulking Gun

- Air Cleaning Gun

- Air Cut-Off Tool

- Air Die Grinder

- Air Drill

- Air Grease Gun

- Air Grinder

- Air Hammer

- Air Impact Wrench

- Air Kits

- Air Nibbler

- Air Ratchet

- Air Riveter

- Air Sandblaster

- Air Sander

- Air Saw

- Air Scaler

- Air Shears

- Air Spray Gun

- Air Tyre Inflator

- Air Nailer

- Air Stapler

- Accessories

- HandTools

-

Machinery

- Excavator

- Woodworking

- Oil Drainer

- Air Cleaners

- Bench Grinders

- Cement Mixer

- Con Saw

- Compressors

- Cut-Off Machines

- Drill Presses

- Dumpers

- Dust Extractors & Vacuums

- Generators

- Hoists

- Hydraulic Floor Press

- Induction Heaters

- Jacks

- Magnetic Drills

- Pipe Bending

- Pressure Washers

- Pumps

- Space Heaters

- Stone Saws

- Tile Saws

- Welding

- Gardening

-

Accessories

- Electrical

- Tie Down & Cords/Straps

- Wheelbarrows

- Workwear & PPE

- Power Tool Accessories

- Adhesives & Tapes

- Sealant & Fillers

- Smoke/Carbon Monoxide Alarm

- Alkaline Battery

- Battery Chargers

- Buckets

- Fastening & Fixings

- Lubricants & Oils

- Padlocks, Door Locks & Security

- Radios

- Spare Parts

- Tool Storage & Access

- Transport Carts

- Work Benches

- Miscellaneous

-

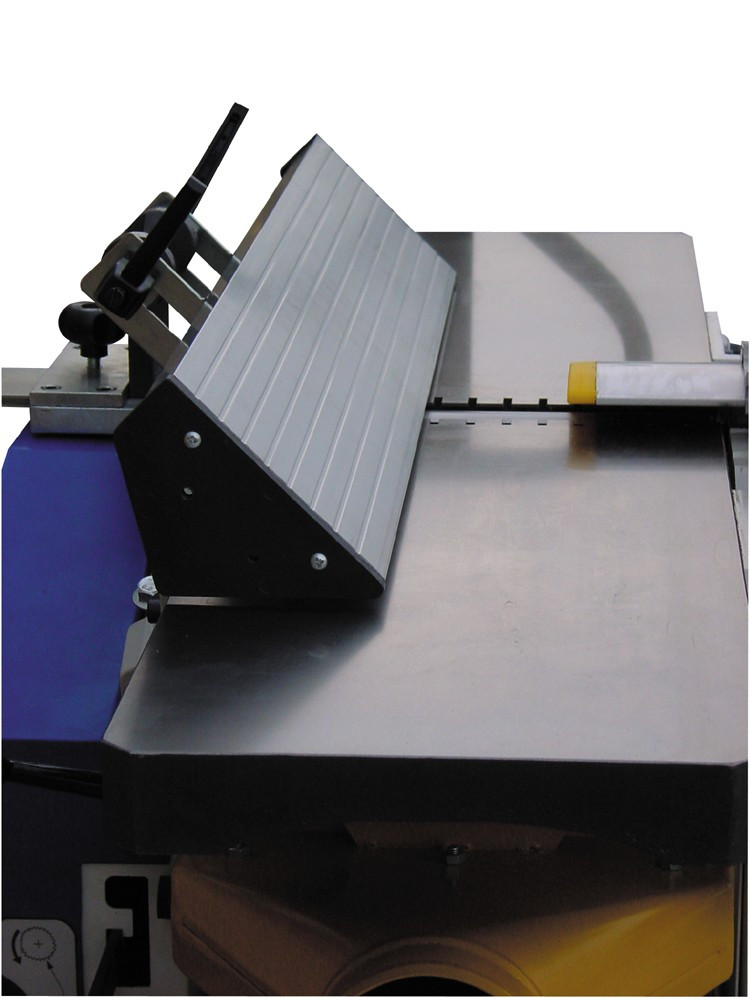

Product Description

A solid and well finished planer thicknesser for the busy workshop.

- Precision Ground Cast Iron Beds

- 2hp Induction Motor

- 3 Knife Cutterblock for Superior Finish

- 10'' Planing Capacity

- 10'' x 7'' Thicknessing Capacity

- Rubber Coated Outfeed Roller

- 100mm diameter Dust Extraction Outlet

- Optional Wheel Base Available

Precision ground cast iron beds and a long tilting fence which can be positioned at any point across the table make this machine a delight to use. The 3 knife cutterblock is powered by a 2hp induction motor and is capable of a cut up to 5mm deep in a single pass.

To gain better visibility and access for thicknessing, both of the planing beds are hinged and swing out of the way, without using any tools. A dust hood / cutter gaurd is then swung into position and the conversion to Thicknesser is complete.

The feed roller drive, which features a rubber outfeed roller, can be disengaged during planing operations to save motor power and general wear on the machine.

Supplied with 3 knives, 100mm dust extraction outlet, 4 adjustable feet, cable and plug.

Our planer thicknesser will run off any standard 13amp supply.Specification

Surfacing width

250mm (10")

Length of surfacing tables

1085mm

Maximum depth of cut

5mm

Fence tilt

90 - 45 degrees

Table height

856mm

Thicknessing capacity

5-195mm (1/4"-7")

Length of thicknessing table

600mm

Feed speed

5.5m/min

Maximum depth of cut

2.5mm

Cutterblock speed

4000rpm

Number of knives

3

Motor ( induction)

1500w (2hp)

Dimensions (WxDxH)

1085mm x 1000mm x 600mm

Weight

150kg

Trade

Warranty 1 Year It is essential to use dust extraction with a planer thicknesser. The extractor removes all the dust and chips which will otherwise build up, causing a blockage and eventually damage to the machine. Using an extractor also increases the life of the knives.

-

Find Similar Products by Category