-

PowerTools

- Corded Power Tools

-

Cordless Power Tools

- Batteries & Chargers

- Belt Sanders

- Biscuit Jointer

- Caulking Guns

- Concrete Vibrators

- Die Grinder

- Dremel Cordless

- Fan

- Heat Gun

- Inflators

- Mag Drill

- Mixing Drills

- Ratchet

- Rebar Bender/Cutter

- Rivet Guns

- Routers

- Staplers

- Vac

- Wall Chasers

- Blowers

- Drills

- Cordless Kits

- SDS Hammer Drills

- Drywall Cut-Out Tool

- Glue Gun

- Grease Guns

- Grinders

- Inspection Camera

- Laser Levels

- Multi Cutter

- Multi-Tools

- Nailers

- Nibbler

- Planers

- Radios

- Sanders

- Saws

- Shears

- Thermometer

- Torch

-

Air Tools

- Air Blow Gun

- Air Caulking Gun

- Air Cleaning Gun

- Air Cut-Off Tool

- Air Die Grinder

- Air Drill

- Air Grease Gun

- Air Grinder

- Air Hammer

- Air Impact Wrench

- Air Kits

- Air Nibbler

- Air Ratchet

- Air Riveter

- Air Sandblaster

- Air Sander

- Air Saw

- Air Scaler

- Air Shears

- Air Spray Gun

- Air Tyre Inflator

- Air Nailer

- Air Stapler

- Accessories

- HandTools

-

Machinery

- Excavator

- Woodworking

- Oil Drainer

- Air Cleaners

- Bench Grinders

- Cement Mixer

- Con Saw

- Compressors

- Cut-Off Machines

- Drill Presses

- Dumpers

- Dust Extractors & Vacuums

- Generators

- Hoists

- Hydraulic Floor Press

- Induction Heaters

- Jacks

- Magnetic Drills

- Pipe Bending

- Pressure Washers

- Pumps

- Space Heaters

- Stone Saws

- Tile Saws

- Welding

- Gardening

-

Accessories

- Electrical

- Tie Down & Cords/Straps

- Wheelbarrows

- Workwear & PPE

- Power Tool Accessories

- Adhesives & Tapes

- Sealant & Fillers

- Smoke/Carbon Monoxide Alarm

- Alkaline Battery

- Battery Chargers

- Buckets

- Fastening & Fixings

- Lubricants & Oils

- Padlocks, Door Locks & Security

- Radios

- Spare Parts

- Tool Storage & Access

- Transport Carts

- Work Benches

- Miscellaneous

-

Product Description

Features

- 6'' Cutting Depth Capacity

- 12'' Cutting Width (Throat)

- Supplied with High Quality British Made Blade

- Precision Ground Cast Iron Work Table

- Quick Action Locking On Rip Fence

- Crosscutting Mitre Guide Included

- Quiet Induction Motor

- Mains Powered LED work Light

- Integral Dust Collection Tray

- Includes Floorstand

- Primarily used for Woodworking

Manufacturer's Overview

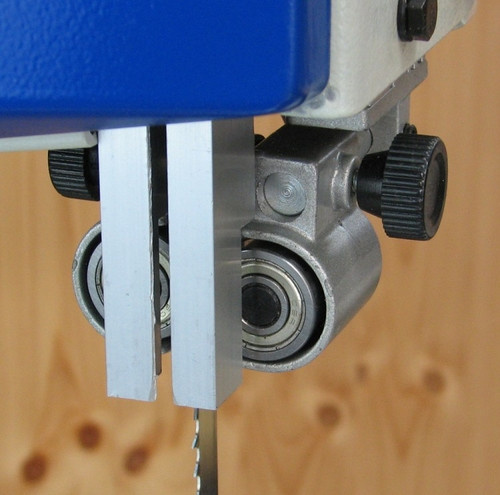

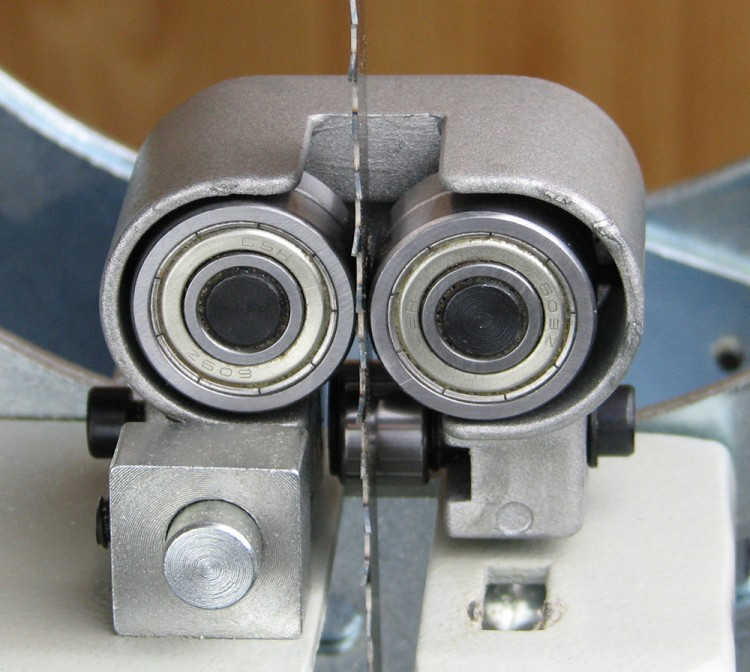

A floorstanding woodworking bandsaw with a cutting capacity of 150mm (6"), big enough for most workshops. The power is delivered by a quiet induction motor with a belt drive to the bandsaw wheel. A two speed pulley allows the correct blade speed to be selected, depending on the hardness of the material being cut. The key to straight and accurate cutting on a bandsaw is to have a good set of blade guides. The B300 has three bearings on the blade guard. The two sealed bearings mounted side-on to the blade, control blade twist and keep it true. The rear bearing takes the thrust of the back of the blade allowing it to run freely. The same setup is then repeated beneath the table.

The cast iron table tilts from 90 degrees to 45 degrees, on a rack & pinion, and has a positive stop at both of those positions. Any angle in between can be read off the scale and locked in. For rip cuts the guide fence can be situated on either side of the blade, can be locked into position with a single press of the lever and has a clear marker to set against the metric scale. The fence itself can be fitted in two ways. When cutting thicker material the full face height of 60mm is used. When cutting thin and narrow strips the fence is fitted with the small face, against the blade to allow clearance around the guides. The bandsaw is fitted with an LED work light on a flexible stem, so that the work area will always be well lit.

The two doors are fitted with safety locks which cut power to the motor when the doors are open for blade changing or cleaning.

Tensioning the blade correctly is made simple thanks to the features on this premium model. A blade tension lever quickly sets the tension. After a blade change fine tuning can be carried out with the aid of a tension indicator and scale. The required tension varies according to blade width. A window in the top door allows the operator to confirm blade tension is correct and make an adjustment when necessary.

A dust extractor is always recommended when using a bandsaw. The dust collection outlet has 3 rings which allow it to accept 3 sizes of hose, 50mm, 75mm & 100mm diameter making it compatible with any type of extraction system. If extraction is not being used however, the bandsaw is fitted with an integral dust collection draw. Dust falling into the base of the machine will be collected here, allowing it to be quickly and easily emptied.

Inclusive

- 1/2'' x 4tpi blade

- Rip fence

- Mitre fence

- Work light

- Floorstand

- Cable and plug

B300 Specifications

Maximum cutting depth 165mm (6") Throat width

305mm (12") Max. cutting width with fence 185mm Left / 180mm Right Table size 480mm x 390mm Table Height 1000mm Table tilt 0-45 degrees Mitre Guide T-Slot 16mm / 20mm Cutting speed 800 & 370m/min Motor (induction) 750w (1hp) Blade length 2240mm Blade widths 6-20mm (1/4" - 3/4") Dimensions (WxDxH) 790mm x 580mm x 1600mm Weight 67Kg Rating Light Trade -

Find Similar Products by Category

-

Other Details

Maximum cutting depth: 230mm (9") Throat width: 345mm (14")` Table size: 545mm x 515mm Table Height: 1020mm Table tilt: 0-45 degrees Cutting speed: 800 & 370m/min Motor (induction): 1100w (1.1/2hp) Blade length: 2560mm Blade widths: 6-25mm (1/4" - 1") Dimensions (WxDxH): 900mm x 720mm x 1720mm Weight: 75Kg